Why Nanofoundry Tech?

We hate rejections, as much as you do.

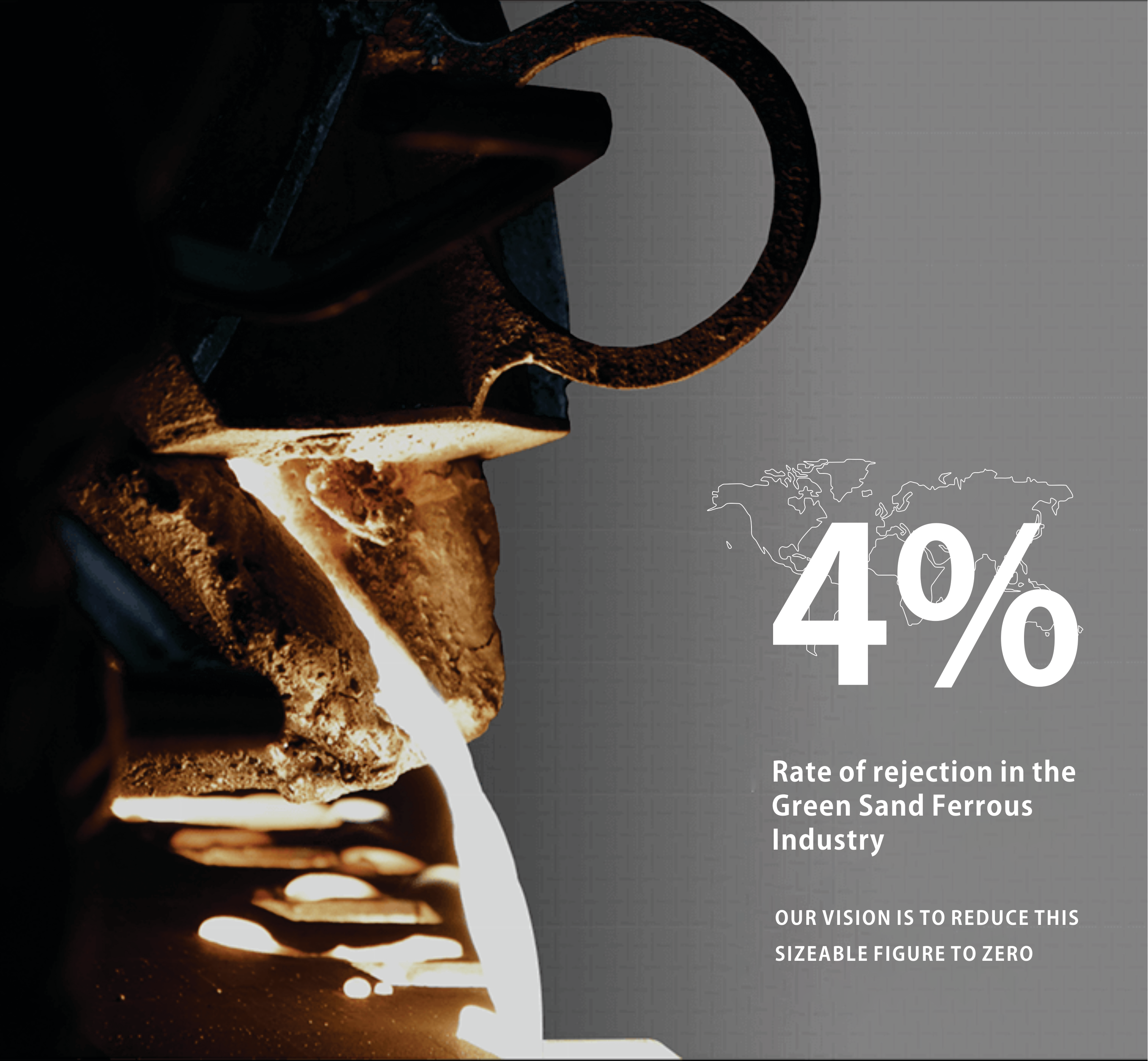

The global rejection average for green sand ferrous foundries stands at 2 percent, while its Indian counterpart unfortunately reads a tall figure of 4 percent. This figure roughly translates to a loss of around INR 12,000 crores

This is where Nanofoundry Tech comes in. We are proud to have indigenously developed products and services that minimise rejections, and maximise savings.

Nanofoundry Tech

Advantages

We understand that each foundry is different. The control factors vary drastically, and this has prevented research bodies from finding precise values that would bring down the rejection percentages.

We use innovative practices with state-of-the-art materials, data mining techniques and machine learning algorithms to understand green-sand systems unique to your foundry. Using this data, we develop customized solutions that suit your foundry.

Once you partner with us, you can witness rejection rates go down within a period of 6 weeks.

Nanofoundry Tech

Process

Our products combine revolutionary new technology and scientifically selected materials, reducing carbon consumption and rejection significantly.

With cutting edge algorithms at our disposal, we help create dashboards that are customized, precise and insightful. Firm believers in green technology, we have in our ranks - the only engineered carbon for green sand in the world, guaranteed to reduce carbon emission by a minimum of 50 percent.

Our Products

Nanokarb

A high performance material that can be used along with your existing carbon additive or as its replacement - Nanokarb ensures supreme finish on your castings in record time.

Mouldmax

A catalyst for bentonite water interaction ensuring that your bentonite is completely activated and eliminate free moisture in the sand system

Copyrights ©2024 All rights reserved by NanoFoundry Technologies LLC